What is Aluminum Die Casting?

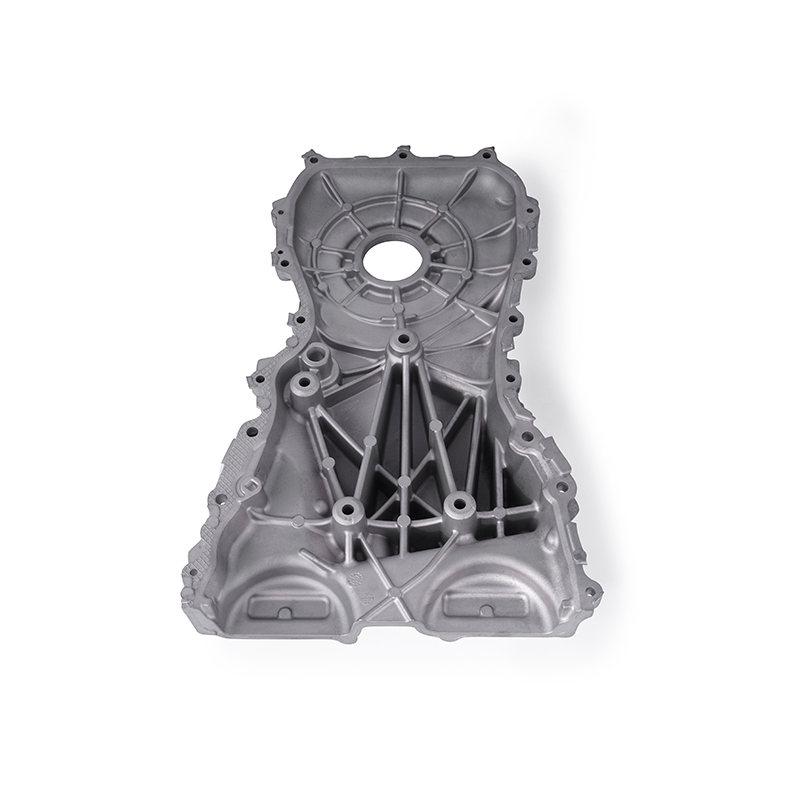

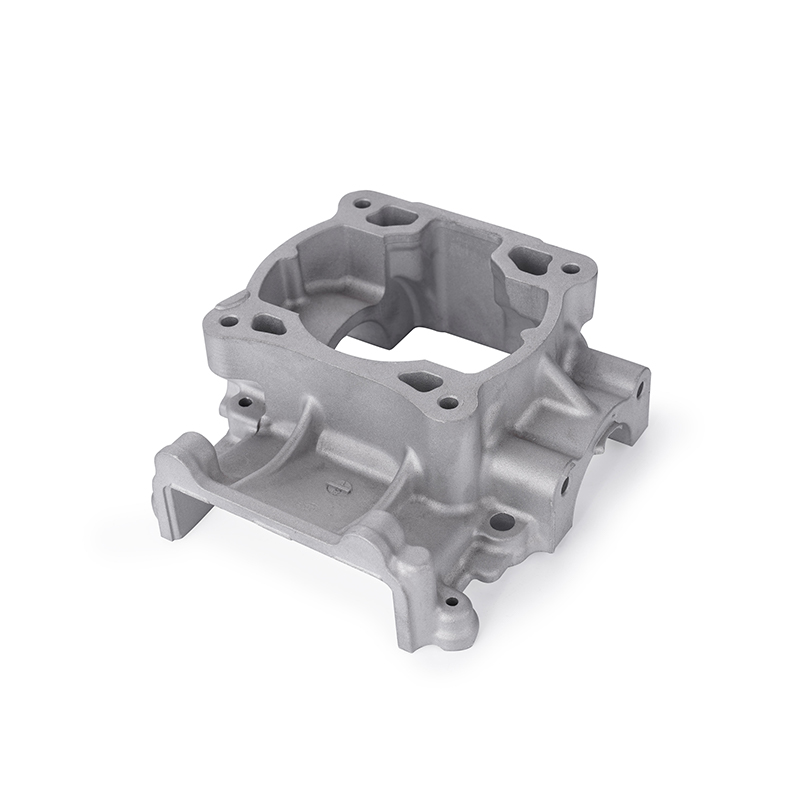

Aluminum die casting is a high-precision casting process commonly used for manufacturing aluminum alloy parts. The process involves injecting molten aluminum alloy into a precisely designed mold under high pressure, where it cools and solidifies to form the desired part. This method enables the production of components with high dimensional accuracy, smooth surfaces, and complex shapes. Aluminum alloys are known for their lightweight properties, excellent strength, and superior corrosion resistance, making them ideal for manufacturing parts that require strict specifications. At Ningbo Jiubao Transmission Machinery Co., Ltd., our advanced aluminum die casting technology plays a key role in the production of transmission machinery and automotive components.

The advantages of aluminum die casting are highly significant, particularly in industries that demand high precision and complex designs for large-scale production. Aluminum die casting allows for high-volume production, where every part produced is consistent in precision and quality. This makes it widely applicable in industries such as automotive, aerospace, and electronics. For instance, at Ningbo Jiubao Transmission Machinery Co., Ltd., our use of aluminum die casting technology enhances production efficiency while ensuring the structural strength and durability of our products.

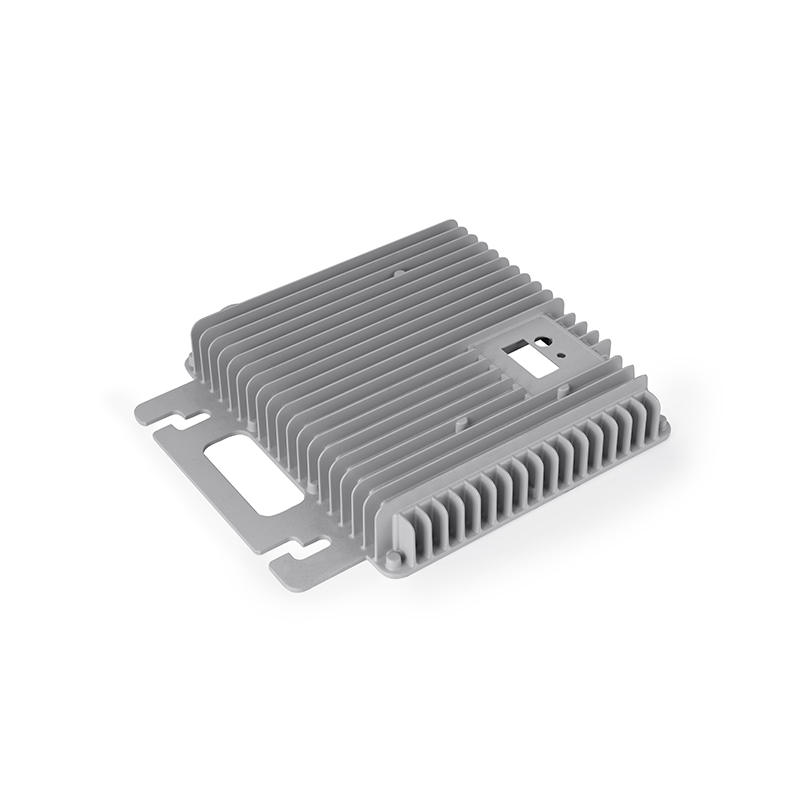

Aluminum alloys have excellent thermal conductivity and a low melting point, making them particularly suitable for applications requiring efficient heat management. Compared to traditional casting methods, aluminum die casting can complete the injection and solidification process in a shorter time, significantly increasing production efficiency. One of the core advantages of this process is its ability to manufacture parts with extremely complex geometries while maintaining high dimensional accuracy.

At Ningbo Jiubao Transmission Machinery Co., Ltd., we utilize advanced Low Pressure Aluminum Casting and High Pressure Aluminum Die Casting technologies to ensure that every transmission component we produce meets exceptional mechanical properties and reliability. Whether for mass production or highly precise components, aluminum die casting technology is capable of meeting market demands and maximizing material and cost efficiency in the production process.

Why is Aluminum Die Casting So Important in Manufacturing?

The importance of aluminum die casting in modern manufacturing is undeniable, especially for large-scale production of parts with high precision and complex geometries. At Ningbo Jiubao Transmission Machinery Co., Ltd., we fully understand this significance, which is why our company is committed to adopting advanced aluminum die casting technologies to improve production efficiency and ensure the highest quality of our parts. Aluminum die casting is not only pivotal in the production of transmission machinery, but it is also widely used across industries such as automotive, electronics, and aerospace.

Aluminum die casting provides remarkable production efficiency. In traditional casting methods, manufacturing a complex aluminum part could take several hours or even days, but with high-pressure aluminum die casting (High Pressure Aluminum Die Casting), the process can be completed in just seconds or minutes. This gives aluminum die casting a significant advantage in mass production. At Ningbo Jiubao Transmission Machinery Co., Ltd., we leverage this advantage to efficiently produce various transmission components, meeting our customers’ stringent requirements for both volume and delivery times.

Aluminum die casting produces parts with high precision. By controlling the injection temperature, pressure, and cooling speed, the process ensures that parts are dimensionally accurate while maintaining smooth surfaces, free from air pockets or cracks. This is crucial in manufacturing mechanical parts that require high reliability, such as those used in transmission systems and other precision machinery. Any small defect in these components could lead to system failures or performance issues, making the use of aluminum die casting in these fields especially important.

Aluminum alloys themselves offer low density and excellent corrosion resistance, which means that aluminum die casting parts are not only lightweight but also have a longer service life. This is particularly beneficial in the automotive industry, where aluminum die casting is widely used to reduce vehicle weight, improve fuel efficiency, and maintain structural strength and safety. At Ningbo Jiubao Transmission Machinery Co., Ltd., our use of aluminum die casting technology ensures that our parts are lightweight while also significantly enhancing their corrosion resistance, thus extending their lifespan.

In the manufacturing of transmission equipment, the application of aluminum die casting technology is indispensable. Low Pressure Aluminum Casting technology can effectively prevent air pockets, improving the density and strength of the parts, further optimizing the performance of the transmission system. By applying these technologies, Ningbo Jiubao Transmission Machinery Co., Ltd. ensures that every part produced can operate stably in demanding industrial environments for extended periods.

What Are the Challenges and Limitations of Aluminum Die Casting?

Despite the numerous advantages of aluminum die casting, there are certain challenges and limitations, especially when producing parts with high precision and complex geometries. At Ningbo Jiubao Transmission Machinery Co., Ltd., we are fully aware of these challenges and continuously focus on technological innovation and lean manufacturing practices to ensure that every product meets the highest quality standards.

Temperature control during the aluminum die casting process is crucial. Due to aluminum’s relatively low melting point and excellent fluidity, precise control over the temperature, pressure, and cooling speed is necessary to prevent defects such as air pockets, cracks, or dimensional inaccuracies. To address this challenge, Ningbo Jiubao Transmission Machinery Co., Ltd. employs advanced mold designs and precise temperature control systems to ensure that every aluminum part meets strict quality and precision requirements.

The cost of manufacturing molds for aluminum die casting can be quite high, especially for parts with complex shapes. While aluminum die casting provides high precision and efficiency, the initial cost of mold production can make it less cost-effective for small-volume manufacturing. This is why Low Pressure Aluminum Casting technology is sometimes more suitable than High Pressure Aluminum Die Casting, particularly in such cases. By selecting the appropriate casting method, Ningbo Jiubao Transmission Machinery Co., Ltd. can flexibly adjust production processes based on customer needs, reducing production costs while increasing efficiency.

While aluminum alloys are known for their excellent corrosion resistance, they may still face challenges under certain harsh environments, such as high temperatures or highly acidic/alkaline conditions. In such cases, the performance of aluminum parts may degrade. To counter this, Ningbo Jiubao Transmission Machinery Co., Ltd. places great emphasis on material selection and surface treatment processes to ensure that our aluminum die cast components perform optimally in demanding environments.

Despite these challenges, aluminum die casting remains one of the most important casting technologies in modern manufacturing. By continuously innovating and refining our processes, Ningbo Jiubao Transmission Machinery Co., Ltd. successfully overcomes these challenges, delivering high-quality aluminum die cast components that meet the diverse needs of various industries.

русский

русский 日本語

日本語