1. What is Iron Casting?

Iron casting is a centuries-old manufacturing process that remains indispensable in producing durable, large-scale components for a wide range of industries. The process involves pouring molten iron into a mold, where it cools and solidifies into the desired shape. Different types of iron, such as gray iron, ductile iron, and white iron, are often selected based on the material properties required for the end product. These characteristics can include strength, hardness, and machinability, and they influence the applications in which the cast iron parts are used.

The Process of Iron Casting at Ningbo Jiubao Transmission Machinery Co., Ltd.

At Ningbo Jiubao Transmission Machinery Co., Ltd., we have extensive experience in the iron casting process, providing our customers with high-quality, robust parts. Our production facility takes advantage of the vast logistical benefits that Ningbo, a manufacturing hub, offers. The city’s proximity to Ningbo-Zhoushan Port, one of the busiest cargo ports globally, allows us to swiftly distribute products to customers across the globe. This is especially beneficial for industries such as automotive, construction, and heavy machinery, which rely on large, durable parts made through iron casting.

Iron casting involves several key steps that are designed to create robust and intricately shaped components. First, molten iron is heated in a furnace until it reaches a liquid state. The iron is then poured into a mold, typically made of sand or metal. As the molten iron cools, it solidifies to form the desired component. After cooling, the iron cast part is removed from the mold, cleaned, and finished to ensure it meets the necessary specifications.

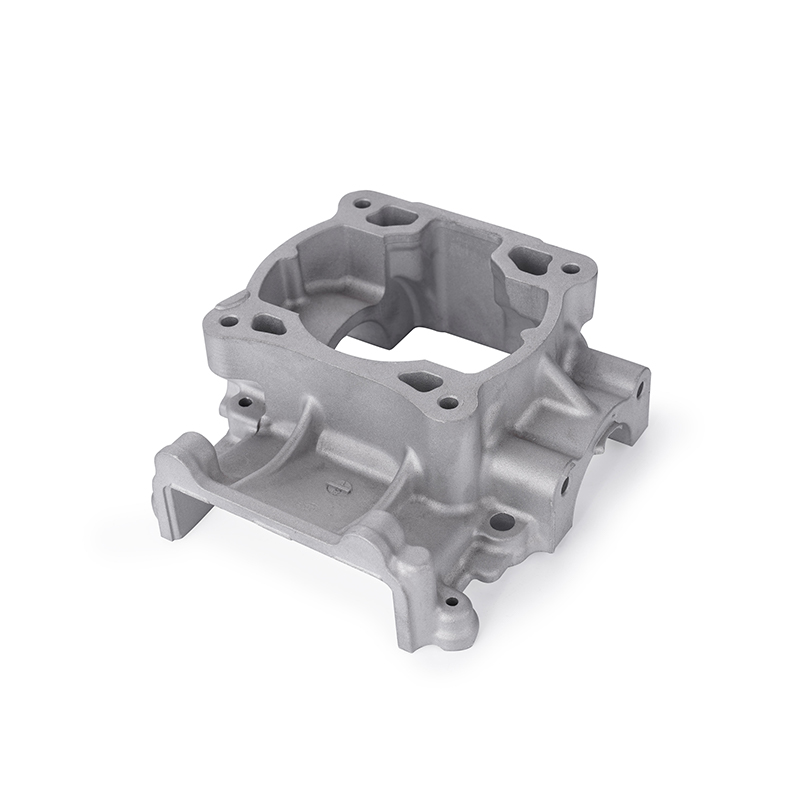

At Ningbo Jiubao Transmission Machinery Co., Ltd., we ensure that every part meets stringent quality standards by employing advanced molding techniques, rigorous quality control measures, and post-production machining when required. This process, while cost-effective for lower to medium volume production, does require additional finishing steps to achieve precise tolerances. However, it’s ideal for producing larger parts with complex geometries, making it an excellent choice for structural components such as engine blocks, housing, and other heavy-duty parts.

Advantages of Iron Casting

The primary advantage of iron casting lies in its ability to produce strong, durable parts that can withstand high-stress environments. Cast iron parts are known for their excellent wear resistance, heat retention, and mechanical strength. Furthermore, the flexibility of iron casting allows for the creation of highly detailed parts, making it a versatile process. At Ningbo Jiubao Transmission Machinery Co., Ltd., we leverage these benefits to deliver products that are both reliable and cost-effective.

2. What is Iron Die Casting?

Iron die casting is a more advanced and precise form of casting that involves injecting molten iron into a reusable mold, called a die, under high pressure. This method is typically used for manufacturing high-precision parts in large volumes, offering faster production speeds and more refined finishes compared to traditional iron casting. Unlike sand casting, which requires the creation of disposable molds for each part, die casting uses permanent steel molds, allowing for repeated production runs without significant mold wear or degradation.

The Iron Die Casting Process at Ningbo Jiubao Transmission Machinery Co., Ltd.

As a company committed to cutting-edge manufacturing practices, Ningbo Jiubao Transmission Machinery Co., Ltd. excels in iron die casting. Our strategic location in Ningbo, with its robust manufacturing ecosystem, allows us to use state-of-the-art die-casting technology to produce highly accurate, durable parts for our clients. The die casting process is especially advantageous in industries where precision is paramount, such as automotive, electronics, and aerospace.

The iron die casting process begins with melting the iron in a furnace, just like traditional iron casting. However, instead of pouring it into a mold, the molten iron is forced into a pre-made die under high pressure. This allows the liquid metal to fill even the finest details of the mold, producing parts with smoother surfaces and tighter tolerances. After the molten iron cools and solidifies, the die opens to release the finished part. This process is highly efficient and can be repeated many times without significant wear to the die.

Benefits of Iron Die Casting

One of the key benefits of iron die casting is its ability to produce parts with extremely high precision and smooth surface finishes. The high-pressure injection process results in components with excellent dimensional accuracy, making it an ideal choice for industries that require small, intricate parts. Additionally, iron die casting allows for the production of parts with thinner walls, reducing material usage and weight, which can be a critical factor in automotive and aerospace applications.

At Ningbo Jiubao Transmission Machinery Co., Ltd., we utilize this technology to produce parts that meet the exacting standards of our global clientele. The high-speed nature of die casting also leads to reduced cycle times, making it more cost-effective for high-volume production compared to other casting methods. Whether it’s for small components like gears and brackets or more complex parts, iron die casting is a valuable process that enables us to deliver fast and precise solutions.

3. Key Differences Between Iron Casting and Iron Die Casting

Iron casting and iron die casting are both used to create metal parts, but the processes, applications, and results are distinctly different. Understanding these differences is crucial for selecting the best method based on the requirements of the project. Here, we highlight the primary distinctions between the two processes and how Ningbo Jiubao Transmission Machinery Co., Ltd. applies them to meet customer needs.

Mold Type:

In traditional iron casting, molds are often made from sand or a combination of sand and other materials, which are relatively inexpensive and flexible but can only be used for a limited number of parts before needing to be replaced. In contrast, iron die casting employs permanent steel molds that can withstand thousands of production cycles without significant wear or deformation. This makes die casting ideal for high-volume production runs.

At Ningbo Jiubao Transmission Machinery Co., Ltd., we are equipped to produce both sand-cast and die-cast components, depending on the nature of the project. For customers needing large, low-volume parts with complex geometries, traditional iron casting is often the preferred method. For projects requiring precise, high-quality parts produced in large quantities, iron die casting is the ideal solution.

Process and Precision:

While both processes involve pouring molten iron into molds, iron die casting involves injecting the molten metal into the mold under high pressure. This results in much more precise parts, with tight tolerances and smooth finishes. Iron die casting is particularly advantageous for parts with thin walls or complex shapes, whereas iron casting may require additional post-processing to remove excess material and achieve the desired finish.

At Ningbo Jiubao Transmission Machinery Co., Ltd., we pride ourselves on our ability to offer both methods, ensuring that our customers get the best possible solution based on their project’s specific needs. Whether it’s for parts that require strength and durability or components needing extreme precision, we can tailor the process to suit.

Applications:

Iron casting is typically used for producing larger, more durable parts such as engine blocks, machine frames, and other heavy-duty components. On the other hand, iron die casting is ideal for producing smaller, more intricate components, often found in industries like automotive, electronics, and medical devices. Die-cast parts are lighter, more precise, and have better surface finishes, making them suitable for consumer products and high-performance machinery.

Ningbo Jiubao Transmission Machinery Co., Ltd. has the expertise and capability to serve both markets, thanks to its strategic location and advanced manufacturing processes. Whether for large, industrial components or precise, high-tech parts, we offer solutions that meet the needs of diverse industries worldwide.

русский

русский 日本語

日本語