Why Choose Our Cast Iron Parts?

In the casting industry, selecting a reliable supplier is crucial, especially for customers who require high-quality cast iron parts. As a professional manufacturer of cast iron parts, Ningbo Jiubao Transmission Machinery Co., Ltd. has many years of experience in providing top-quality castings. We specialize in delivering customized cast iron solutions across various industries, including automotive, machinery, construction, and agriculture, meeting high standards of performance.

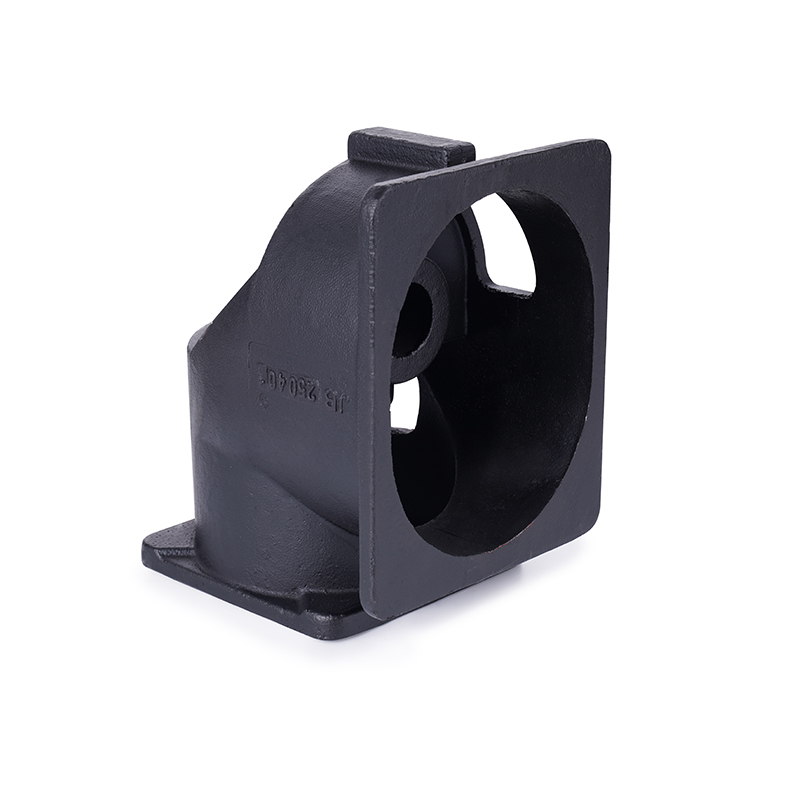

Our cast iron manufacturing process incorporates advanced casting techniques such as Lost Foam Casting, Full Mold Casting, and Gray Iron Casting. These technologies enable us to deliver precise, efficient, and durable cast iron products across different applications. Our gray iron castings are particularly suitable for high-load and high-impact environments, widely used in mechanical equipment and automotive components.

Ningbo Jiubao Transmission Machinery Co., Ltd. is committed to continually improving our casting processes to ensure that every cast iron product you receive is of the highest quality. By combining modern production techniques with a strict quality management system, we guarantee that every cast part meets international standards, helping you gain a competitive edge in the market.

How Do Our Cast Iron Parts Meet Your Rigorous Demands?

Different industries and applications require different types of cast iron parts. We understand that each customer has unique needs, and as a leading cast iron parts manufacturer, Ningbo Jiubao Transmission Machinery Co., Ltd. is dedicated to providing customized solutions. Whether you need gray iron castings for high-pressure environments or high-precision cast iron parts using Lost Foam Casting, we can provide the most suitable product for your requirements.

Our Lost Foam Casting process allows us to manufacture high-precision, complex-shaped cast iron parts, making it ideal for industries with high precision demands. This technique is particularly useful for small-batch, multi-variety production and for casting parts with complex geometries. In addition, our Full Mold Casting process, using high-precision molds, improves the dimensional accuracy and surface finish of the cast iron parts, further enhancing their durability and reliability.

Throughout the process of meeting your rigorous demands, our professional team provides full technical support. From initial design consultation to production and quality control, we ensure that every batch of cast iron parts perfectly matches your requirements. We adhere to international quality standards, such as ISO 9001, ensuring the highest quality at every stage of production. Whether you need a single custom part or large-scale production, we offer flexible delivery times while maintaining product quality.

Why Is the Quality of Cast Iron Parts Crucial for Your Products?

The quality of cast iron parts directly affects the performance and longevity of the final product. In many high-precision, heavy-duty applications, poor-quality cast iron parts can lead to equipment failure, production downtime, or even safety hazards. Therefore, selecting a supplier with a reliable quality control system is key to ensuring the long-term, stable operation of your products.

As a company with years of industry experience, Ningbo Jiubao Transmission Machinery Co., Ltd. understands that the quality of cast iron castings is critical to the stability and competitiveness of your products. We insist on using the most advanced technology and equipment, along with a variety of casting processes (such as gray iron casting and Lost Foam Casting), to ensure that every cast iron part has excellent physical properties, such as wear resistance, corrosion resistance, and shock resistance, which are crucial for extending the service life of your equipment.

Throughout the production process, we use advanced testing equipment to conduct comprehensive quality inspections, ensuring that every cast iron part meets strict standards in terms of size, strength, hardness, and other physical properties. For example, gray iron castings, produced using our specialized process, typically offer better fluidity and lower cost, making them ideal for mechanical equipment and heavy industrial machinery. We also focus on surface treatment techniques, ensuring that every cast part is ready for subsequent processing with minimal waste and difficulty.

At Ningbo Jiubao Transmission Machinery Co., Ltd., we are committed to providing our customers with cast iron products that meet rigorous quality standards. Through professional service and continuous innovation, we help customers enhance their product competitiveness and ensure that their products perform reliably in their respective markets.

русский

русский 日本語

日本語